- Porsche is advancing the recycling of EV batteries through its innovative processes, focusing on sustainability and quality.

- The creation of “black mass,” a powder from recycled batteries, is pivotal for extracting valuable materials like nickel, cobalt, manganese, and lithium.

- The process ensures high-purity elements are reused in new battery cells, maintaining Porsche’s performance standards.

- Porsche aims to incorporate recycled content in battery cells for future vehicles, demonstrating a strong commitment to sustainability.

- Anticipating EU regulatory changes by 2031, Porsche’s early action positions them as industry leaders in sustainable automotive production.

- This initiative not only guarantees compliance but sets a new benchmark, proving that luxury and sustainability can coexist.

- Porsche’s approach highlights a proactive stance, encouraging the automotive sector to prioritize responsible resource management.

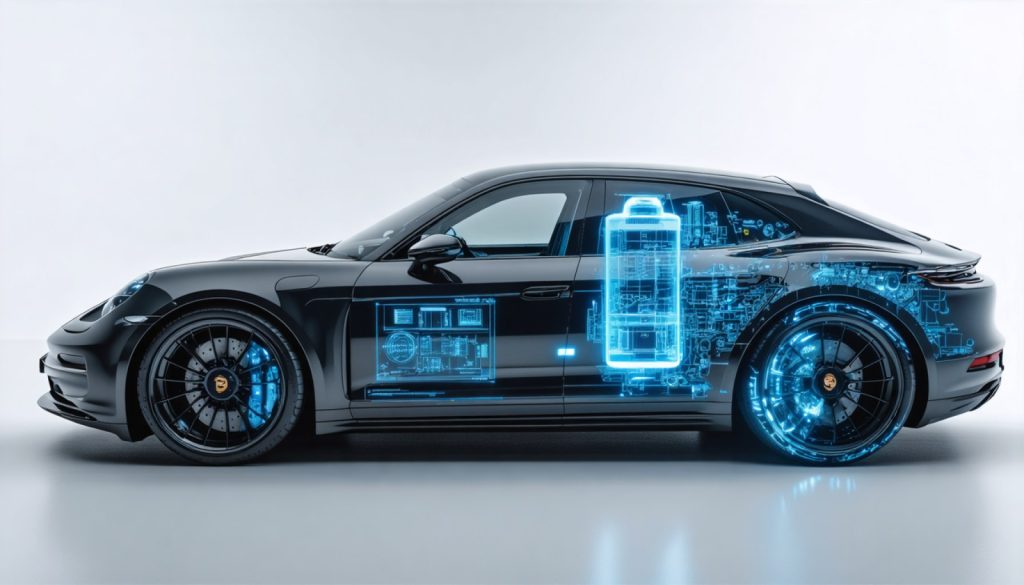

Through the glass doors of cutting-edge laboratories blanketed with the hum of innovation, an ambitious enterprise unfolds. Porsche has embarked on a daring journey to revolutionize the fate of its electric vehicle (EV) batteries. Clad in lab coats, scientists work diligently to bring new life to materials once deemed spent and scrapped. This groundbreaking initiative isn’t merely about recycling; it’s about building a sustainable future with the vigor of a world-class automobile brand.

The epitome of transformation lies in the creation of “black mass”—a mystifying yet critical byproduct of the recycling process. Here lies the genius of engineering: old batteries go through mechanical shredders, emerging as a fine powder rich in precious materials. Nickel, cobalt, manganese, and lithium—the elements that once powered luxury vehicles—are reborn, ready for a new chapter. In an impressive feat, Porsche has crafted 65 tonnes of this coveted granulate, showcasing their deft ability to transform waste into resources.

The real magic takes place when “black mass” is meticulously refined. Only through this process can high-purity elements be extracted, essential in crafting batteries that uphold Porsche’s renowned quality standards. Imagine the precision required—the consistency, the cleanliness—as technicians ensure each granule contributes to the performance excellence customers expect from a Porsche.

Looking to the horizon, Porsche’s vision transcends current market demands. The firm readies itself to integrate a specified share of recycled content into battery cells destined for the next generation of vehicles. This daring aspiration is much more than a nod to sustainability; it’s a bold declaration of Porsche’s commitment to leading the charge. The company recognizes that the ecological and geopolitical landscapes are changing, and navigating these waters requires innovation.

With whispered winds of regulatory changes from the European Union, Porsche’s early adoption signals its foresight. The upcoming decade will witness stricter mandates on recycled content, and Porsche is poised to meet and exceed these standards. Their pilot project not only exemplifies their dedication to responsible resource management but solidifies their role as a vanguard in sustainable automotive production.

As European countries brace for the new battery regulations by 2031, Porsche’s initiative not only guarantees compliance but sets a benchmark. The narrative here is one of proactivity, of being ahead of the curve, and of a storied brand redefining luxury—not just in terms of car performance, but in their ecological footprint.

Porsche’s strategy is clear and compelling—transforming what was once perceived as mere waste into a treasure trove of opportunities. Their pioneering spirit will likely ignite similar flames in the automotive landscape, challenging others to follow suit. The message rings loud: sustainability and luxury can indeed be partners soaring towards a responsible future.

Porsche’s Revolutionary Move: Elevating EV Battery Recycling to New Heights

Revamping Sustainability in the Automotive Industry

Porsche’s newly unveiled initiative highlights a significant shift in the automotive industry towards sustainable innovation. By converting old electric vehicle (EV) batteries into “black mass” and extracting high-purity elements, Porsche is setting a new standard for luxury brands to follow.

The Science Behind “Black Mass”

The core of Porsche’s transformation lies in “black mass,” a vital product derived from the recycling of old batteries. But what makes this transformation truly revolutionary lies in the materials harvested from this process: nickel, cobalt, manganese, and lithium. These elements are reclaimable and crucial for making new, efficient battery cells that meet Porsche’s high standards.

How Porsche’s Initiative Stands Out

1. How-To Steps & Life Hacks

– Battery Collection and Shredding: Used batteries are collected and processed through mechanical shredders.

– Separation Process: The shredded materials are meticulously sorted to isolate the useful elements.

– Refinement of Black Mass: Advanced techniques extract high-purity materials, primed for new battery production.

2. Real-World Use Cases

– Reduced Dependency on Raw Mining: By reusing materials from “black mass,” Porsche diminishes the need for environmentally taxing mining operations.

– Economic Efficiency: Saves costs on acquiring virgin materials, repurposing waste into valuable resources.

3. Market Forecasts & Industry Trends

– Increased Adoption of Recycled Materials: As environmental regulations tighten, expect a surge in recycled content use across all major automotive brands.

– European Union Regulations: By 2031, the EU will enforce higher recycled material quotas, propelling industry-wide changes in production practices.

Pros & Cons Overview

Pros:

– Promotes environmental sustainability through resource efficiency.

– Ensures compliance with future regulatory mandates.

– Enhances Porsche’s brand image as an eco-conscious leader.

Cons:

– High initial investment in recycling technology.

– Requires rigorous quality control to meet luxury standards.

Insights & Predictions

– Porsche as a Trendsetter: Porsche’s proactive steps are likely to influence other automakers, prompting more brands to invest in sustainable practices.

– Improved Battery Performance: Recycled materials could enhance battery life and performance, crucial for keeping up with consumer expectations.

Actionable Recommendations for Sustainability

– Invest in Recycling Technologies: Automakers should increase funding for recycling technologies to prepare for stricter regulations.

– Collaborate with Regulatory Bodies: Engage with policymakers to stay ahead of legislative changes.

– Enhance Consumer Awareness: Educate customers on the benefits of sustainable technologies to drive demand for eco-friendly vehicles.

For more insights on Porsche’s initiatives and their vision for sustainable luxury automotive production, visit their official website: Porsche.

In conclusion, Porsche’s strategy to transform EV battery recycling into a hallmark of sustainability marks a turning point in luxury automotive manufacturing. By leading with innovation and a commitment to environmental responsibility, Porsche not only meets upcoming standards but sets a powerful example for the entire industry.